As a new type of light source, solid-state white light lighting (LED or LASER) will become an inevitable trend to replace existing fluorescent lamps, incandescent lamps and other gas light sources. However, as the brightness of light source products is required to become higher and higher, this However, the packaging process is stretched thin. Currently, the biggest obstacle restricting the international development of China's lighting industry is the lack of core patents on materials, especially fluorescent materials, which are completely monopolized by large foreign manufacturers. If you want to break through patent barriers, you can only independently develop new core materials. Xinda's ceramic phosphors and glass phosphors replace traditional silicone phosphors, which can not only break through international patent barriers, but also significantly improve the reliability of packaging materials and maintain or improve optical efficiency.

Advantages of inorganic phosphors

High reliability features

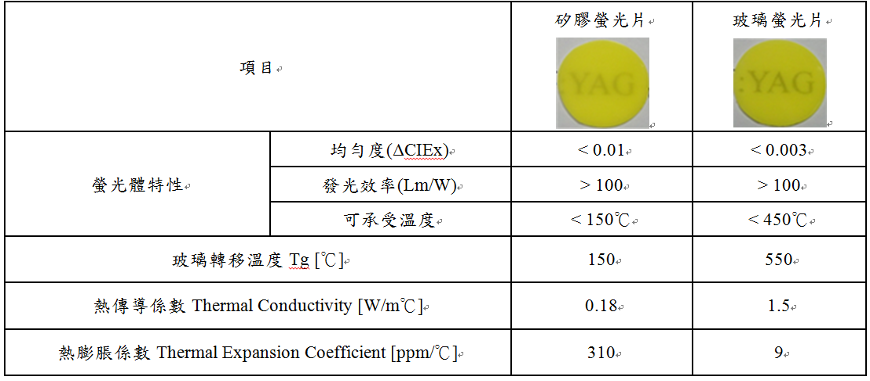

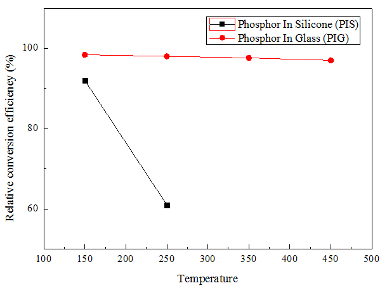

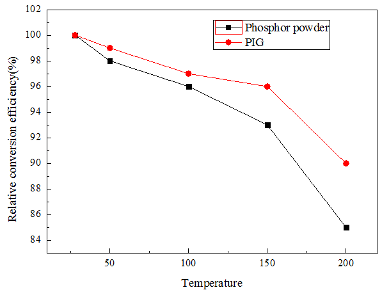

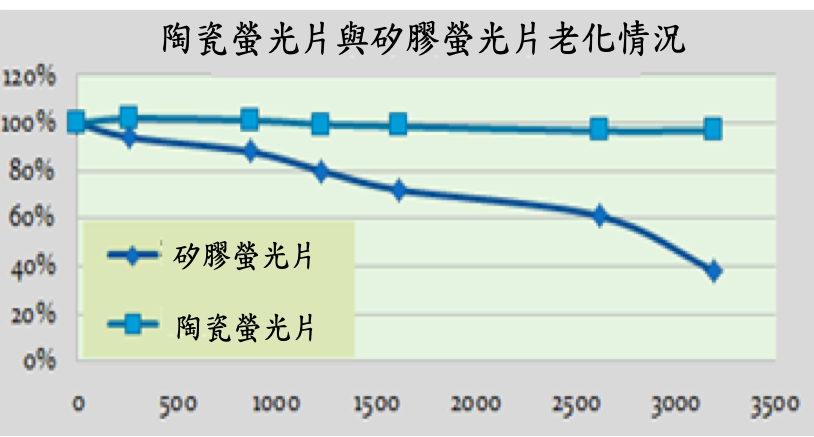

The biggest advantage of inorganic phosphor materials is high reliability. According to internal experimental tests, the luminous flux of traditional organic silicone phosphors dropped by 8% after aging testing at 150°C for 1008 hours, while inorganic phosphors experienced an aging test at 150°C for 1008 hours. After that, the luminous flux only dropped by 1.6%. After the traditional organic silicone phosphor was aged for 1008 hours at 250°C, the luminous flux dropped by 39%. After the inorganic phosphor was aged at 150°C for 1008 hours, the luminous flux only dropped by 2%. The reason is that the glass transition temperature (Tg) of inorganic phosphors is much higher than that of traditional organic silicone phosphors, so they are suitable for high-power lighting applications (operating temperatures above 80~150°C). It is expected that they will be used in high-power lighting fields in the future. There will be revolutionary technological improvements and a broad application market.

Color temperature uniformity and color temperature customization

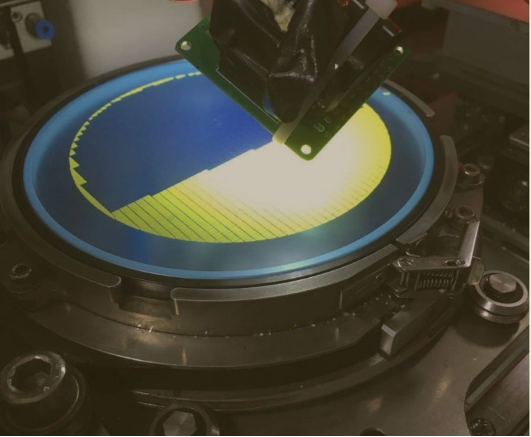

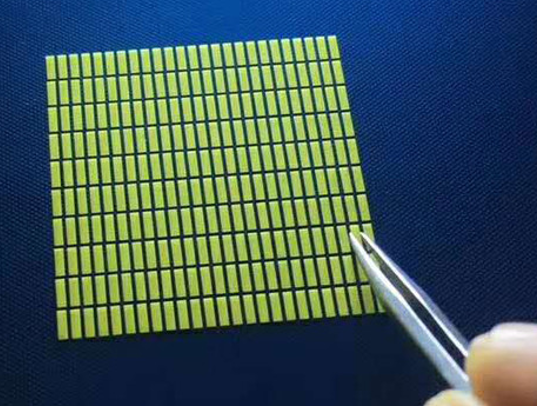

In the production process of glass and ceramic phosphors, the phosphor powder and glass powder or ceramic powder are mixed in proportion and then fired. The color uniformity after molding is high, which fundamentally avoids the dispensing process in the existing packaging process. If there is a color difference phenomenon, you can also select the corresponding phosphor according to the wavelength of the blue light crystal to ensure the color temperature consistency of batch shipments, as shown below. On the other hand, inorganic phosphor sheets with corresponding color temperatures can also be customized for different application fields, as shown below.

Nonporous inorganic phosphor

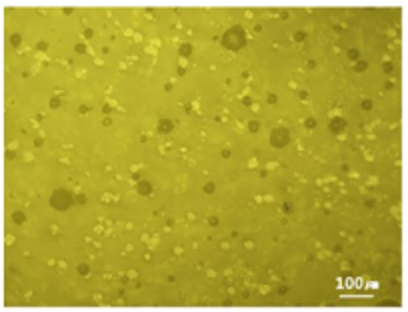

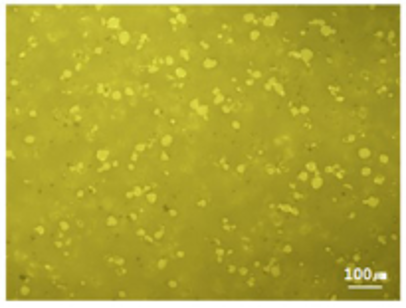

The quality of inorganic phosphors on the market varies from good to bad. This inorganic phosphor is a product of mixing and sintering glass powder and phosphor powder. The gaps between the powder particles will form bubbles after sintering, as shown in the picture on the left. The internal pores of inorganic phosphors will cause a large amount of scattering, resulting in a decrease in transmittance, thus reducing luminous efficiency. Second, if the material is used for high-power lighting, the internal pores are susceptible to high temperatures, causing the phosphor sheet to break. Our company uses a unique process to prepare non-porous inorganic phosphors, which will greatly improve the breakage probability of inorganic phosphors, increase the mechanical properties of inorganic phosphor sheets, and improve the luminous efficiency of inorganic phosphors.

High chemical stability properties

Traditional silicone is water-absorbent. When used in harsh environments, especially in acidic environments, it can easily lead to oxidation of the silver coating, resulting in drastic changes in color temperature. Ceramic phosphors have stable chemical properties and high density. It can fundamentally solve industry problems such as oxidation of silver plating and aging of phosphor powder, making the lighting source colorless and extending its service life.

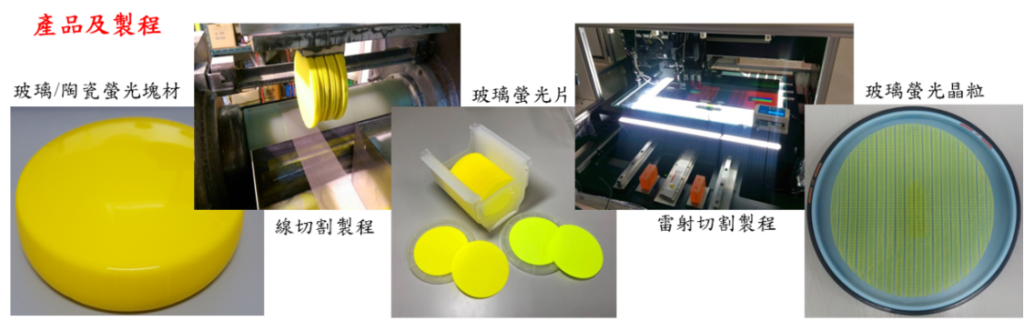

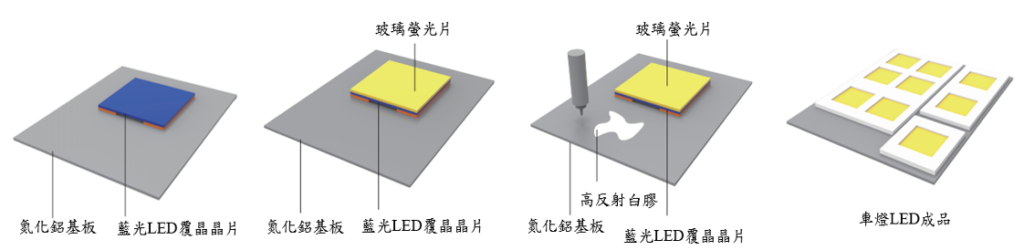

Product manufacturing process and application

The process and application methods of glass and ceramic phosphors are shown in the figure below. After optical design, this material can be used with LED and Laser light sources for automotive lights, displays, flashes, stage lights, projectors and other lighting applications.